CUSTOM LAB MACHINIST CONSULTING SERVICES:

CREATIVE DESIGN SERVICES

Many of our projects involve design of novel tools and assemblies. We develop creative design solutions to a wide variety of problems in science and engineering, ranging from cutting edge apparatus to manufacturing tooling. Our capabilities include:

State of the art CAD and simulation tools from Siemens NX and Solid Edge

Broad expertise with materials, manufacturing and automation methods

A focus on designing for simplicity and manufacturability

3D printing, fabrication and machining of rapid prototypes

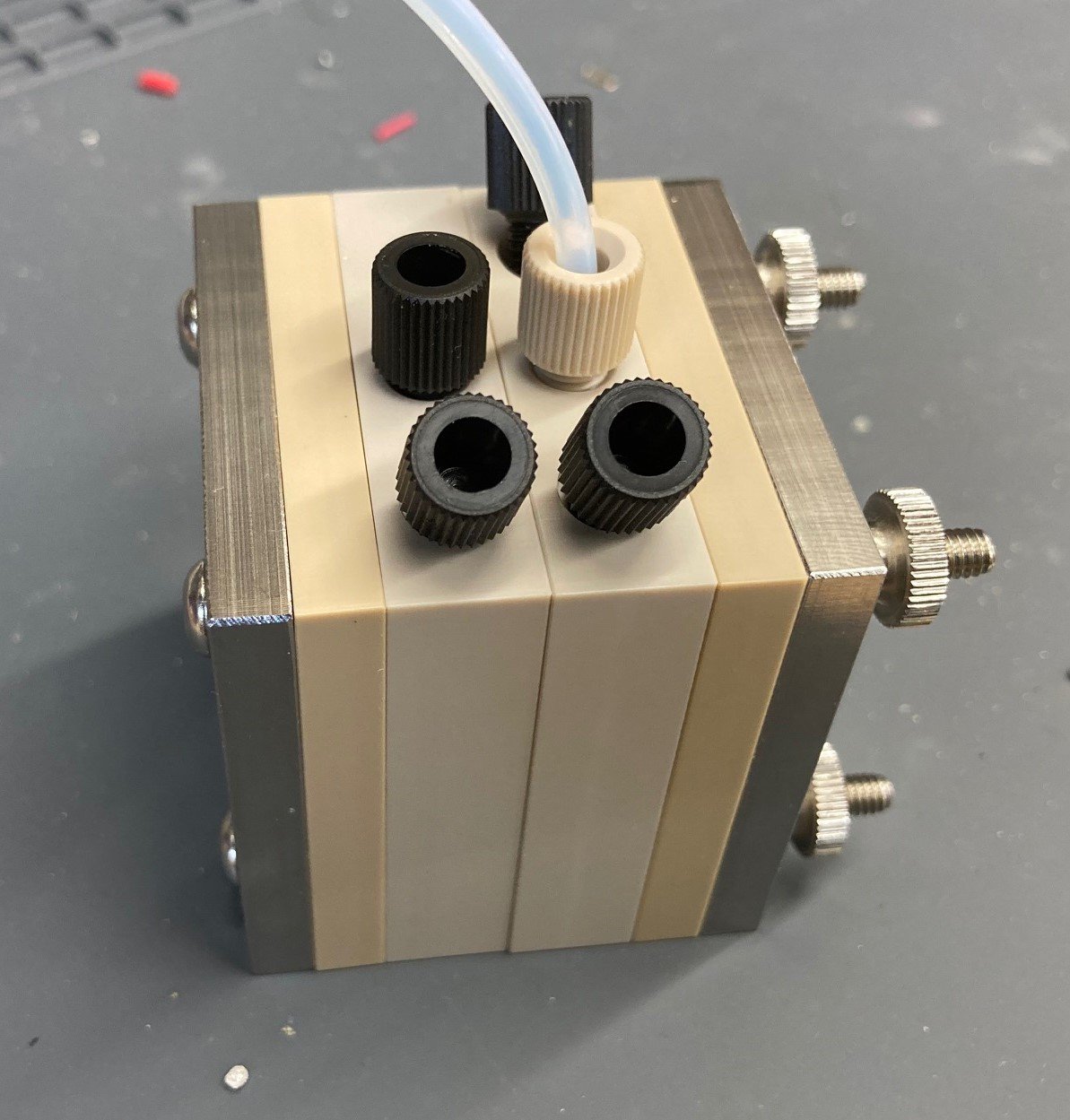

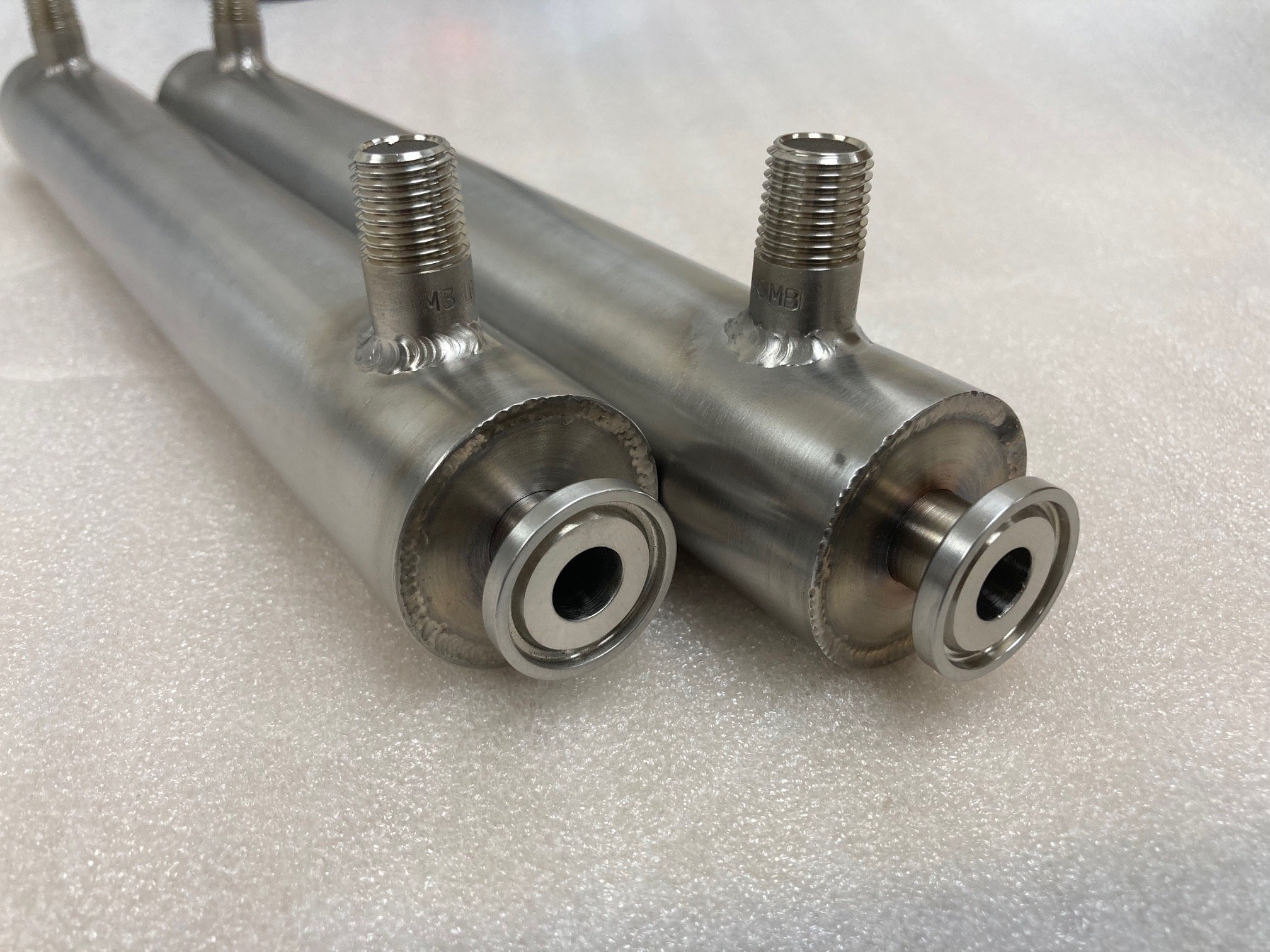

Machining and Fabrication OF CUSTOM APPARATUS AND PROTOTYPES

We can take your idea from concept to production. In our own shop we can provide:

Machining of all materials, from plastics to aluminum, titanium and hardened tool steel.

Laser cutting with a 1KW fiber laser for high-precision cutting of stainless steel, aluminum and other sheet metals, and a 120W CO2 laser for marking and cutting of plastics and other soft materials.

TIG welding including vessels, sanitary, corrosive process and vacuum applications.

Precise fabrication of tubing assemblies, weldments and densely packed coils.

FDM 3d-printing.

Production of complete assemblies including custom parts, electronics, welding, fluidics and hardware.

We also help you access countless other services through our partner shops. Common needs include high-quantity machining, heavy fabrication, glassblowing, water jet cutting, injection molding, and coating/plating services.

CONSULTING AND PROJECT MANAGEMENT

We contribute unique value to your projects with:

Love of science and a can-do approach to every problem

Broad knowledge of research methods, tools and instrumentation

An experienced eye toward customization and optimization of lab processes

Established relationships with local suppliers and services

Ability to work with the Quality Systems requirements of clients, including those with ISO 13485 and ISO 9000 certification processes.